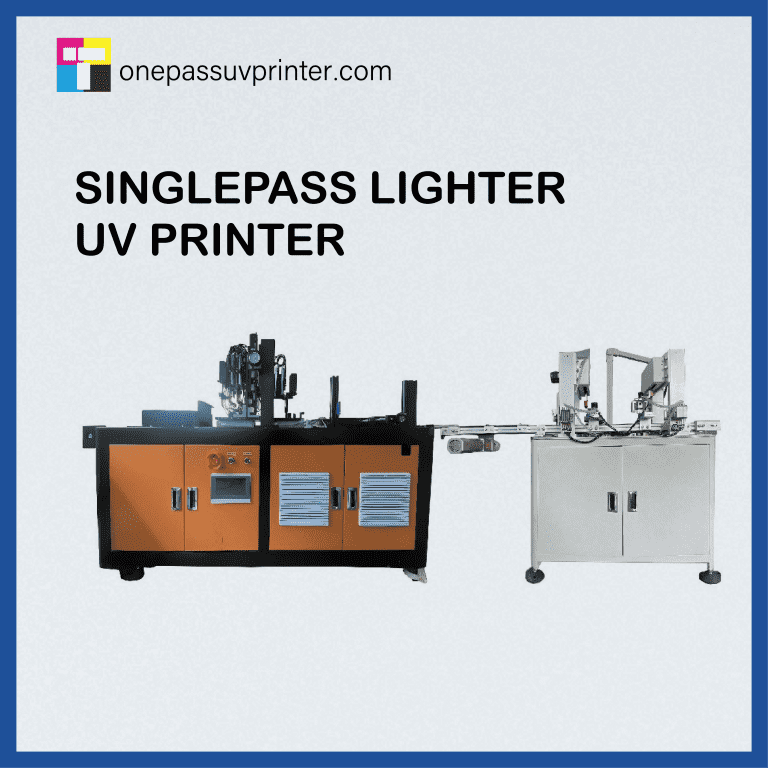

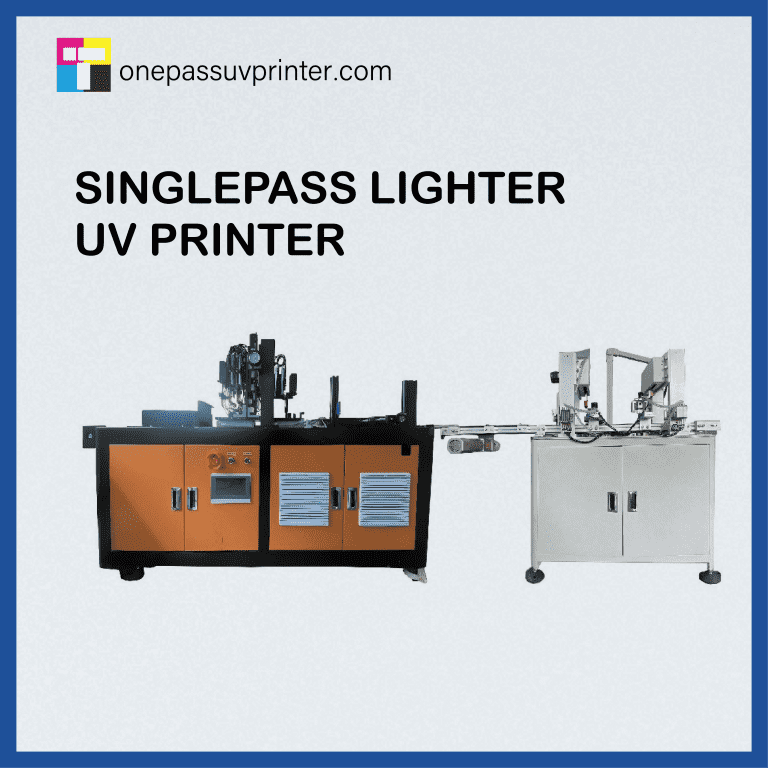

Packaging print domain is evolving markedly with the rise of advanced one-pass UV platforms. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. With instant ultraviolet curing of inks and coatings, single-run UV printing avoids slow drying and repeat passes, lowering production expense and duration.A major strength lies in delivering bright, long-wearing prints on many materials including polymer, metal, and textile surfaces. Top-tier resolution in single-pass UV generates precise image and typographic detail, excellent for packaging, signage, and marketing items. Further, its efficient energy usage compared with traditional printing supports greener production practices.

Packaging print domain is evolving markedly with the rise of advanced one-pass UV platforms. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. With instant ultraviolet curing of inks and coatings, single-run UV printing avoids slow drying and repeat passes, lowering production expense and duration.A major strength lies in delivering bright, long-wearing prints on many materials including polymer, metal, and textile surfaces. Top-tier resolution in single-pass UV generates precise image and typographic detail, excellent for packaging, signage, and marketing items. Further, its efficient energy usage compared with traditional printing supports greener production practices. The rollout of single-pass UV opens novel opportunities for companies to elevate printing capabilities.

The rollout of single-pass UV opens novel opportunities for companies to elevate printing capabilities. Single-Pass UV Trends

Digital high-speed printing historically pursues efficiency. Formerly this involved successive ink passes, increasing lead time and alignment errors. However, the rise of Single-Pass UV is upending traditional approaches. This innovative technology uses ultraviolet light to instantly cure inks in a single pass, resulting in dramatic improvements in speed and precision.Single-Pass UV renders lively colors with incredible clarity and depth of detail. Accordingly it’s optimal for areas like high-volume packaging, display production, and promo materials where throughput and appearance are essential. As the technology continues to evolve, we can expect even more groundbreaking advancements in Single Pass UV printing, paving the way for a future of truly high-speed, versatile, and cost-effective digital production.

Single-Pass UV Printers: Speed Meets Accuracy

In the competitive printing field, single-pass UV printers represent a breakthrough redefining rapid output, accuracy, and workflow efficiency. These systems apply ultraviolet curing to harden inks on contact, producing exceptional throughput. Their multi-color single-pass capability delivers superior resolution and lively color reproduction. From personalized products to high-volume commercial printing, these versatile machines cater to a wide range of applications, empowering businesses to meet the ever-increasing demands of today's market.Enhance Your Printing Output

Expect to be impressed by the single-pass UV printer — a strong solution transforming industry norms. This cutting-edge device harnesses ultraviolet light to cure inks in one pass, providing excellent print clarity and resolution.- Enjoy vivid hues with unmatched accuracy

- Boost your production speed with rapid printing capabilities

- Expand new creative possibilities with a wide range of printable materials

Accelerated UV Printing: Delivering Unmatched Efficiency

UV printing has revolutionized the graphics industry with its speed, precision, and vibrant colors. High-speed UV elevates those strengths further, enabling exceptional production efficiency. The approach uses dedicated printers engineered to produce high-res images at very high speeds. With instant UV cure and limited drying, accelerated UV printing refines operations for fulfilling high-pressure orders. High-speed UV advantages go further than simple efficiency gains. It achieves remarkable print excellence, resilience, and suitability for many applications. From product packaging to banner production and label runs to marketing signage, high-speed UV changes operations so businesses can adapt and lead.

Rapid Printing: The Ultimate Solution for Fast Turnaround Times

In today’s rapid-paced landscape, speed is key. For printing, businesses require fast, efficient solutions. This is where One-Pass Print plays a role. The system supports one-pass prints, eliminating repeat runs and reducing overall process time. One-Pass Print enables greatly faster turnarounds, freeing staff and resources. Therefore, organizations across sizes can leverage One-Pass Print advantages. From creating marketing materials to producing essential documents, this technology empowers you to print what you need, when you need it, without compromise.Single-Pass UV: Precision at Speed

In modern production ecosystems, efficiency is the key priority. Producers want solutions that keep quality high and production fast. Single-Pass UV stands out as a revolutionary method uniting precise inspection with fast curing. This process uses immediate UV curing of inks and coatings to produce vivid durable finishes while shortening production time. Inherent accuracy in single-pass UV yields impeccable products that meet high-quality thresholds. Advantages go further than just speed and quality. Single-pass UV cuts waste by removing long drying periods, aiding sustainable manufacturing.- Furthermore, the broad applicability of single-pass UV spans packaging, printing, and electronics production.

Advancing Digital Printing via Rapid UV

The printing industry is continually evolving, driven by a constant demand for faster speeds, greater precision, and innovative solutions. High-speed UV appears as a pivotal innovation that blends speed, precision, and adaptability. The instant ink curing of UV printing eradicates long drying times and broadens the scope of printing applications. This fast curing mechanism supports superior print speeds, markedly reducing production time and enhancing efficiency. Additionally, UV inks show great durability and resistance to fade, abrasion, and moisture, suiting many uses. From striking displays to durable package printing, rapid UV printing transforms how prints are made.- Pros

Fast Prints Now: One-Pass UV Printers Revolutionizing Output

Across graphics and design industries, time is a scarce commodity. Customers require fast delivery times while businesses must supply top-quality prints on demand. One-pass UV printers address this digital printer need by providing an innovative solution for modern printing. Advanced systems apply UV inks that cure immediately under illumination, removing drying wait times. Result: immediate prints showcasing lively colors and robust finishes. As such, single-pass UV printers apply to many different industries. From retail, e-commerce, and marketing to photographic, fine-art, and manufacturing uses, businesses utilize instant printing. Use cases range from custom product creation to bespoke signage and striking marketing materials. Benefits extend past quickness and efficiency gains. Single-pass UV printers ensure accurate color, fine resolution, and substrate flexibility for rigorous projects.- Furthermore, single-pass UV is sustainable because it uses no harsh solvents or VOCs.

- Finally, the instant-print era has begun—single-pass UV’s speed, versatility, and print quality are reshaping workflows for a more efficient future.

Optimize Operations with Single-Pass UV

Simplify production workflow and access higher efficiency using a single-pass UV printer. This modern solution prints vivid, high-resolution images on many substrates in one run, bypassing multiple layers.- Realize superior speed and shorten production durations.

- Boost throughput with quicker order turnaround.

- Rely on UV ink precision and durability for sustained bright results.

Single-Pass UV: Boosting High-Impact Print

Single-pass UV has changed the landscape for high-impact printing. The technique applies ultraviolet curing for inks, offering notable improvements over legacy methods. Initially, single-pass UV offers superior image quality through intense colors and fine detail. Curing instantly removes drying delays, boosting productivity and shortening turnaround.- Moreover, the method creates hard-wearing prints that resist fading, scratching, and abrasion.

- In brief, exceptional visuals, greater productivity, and durability establish single-pass UV as a top pick for high-impact printing.